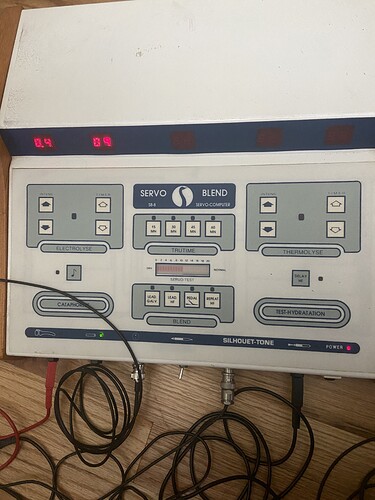

Hi, I just purchased a Silhouet Tone Servo Blend. I read the instruction manual but and the machine lights up/turns on etc however , when I insert the probe&needle, nothing happens. I tried both the thermolysis and galvanic . Please advise as I’m not sure if I’m even starting the machine right. I have attached pictures below .

If you have experience with this machine or similar ones please let me know if I could ask you some questions regarding usage.thank you in advance

Okay Ruby lets break it down. I will say I have never used a sil-tone servo-blend and I’m not familiar with it’s settings but I understand they are simple machines in use- When they work properly. They are very much older machines now and ccalibration and testing is IMPERATIVE before they are ever used on human skin. You’ve been warned!. I’m hoping an electrologist who worked with one once might hop in and help out with he controls.

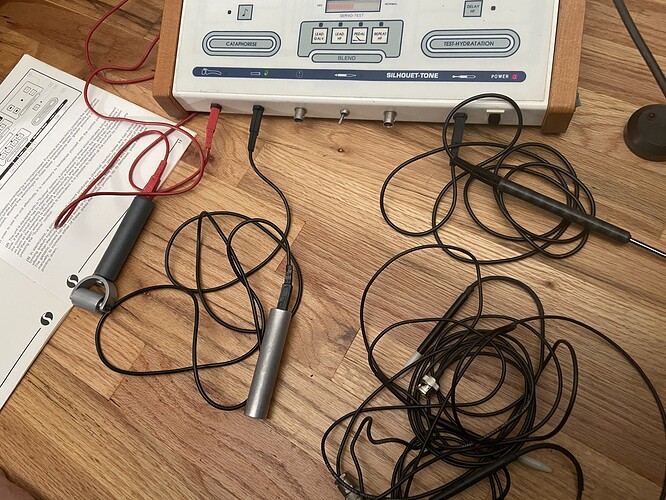

First lets check the component hookups. You’ll want a multimeter to test continuity of all cords and wires. Set it to beep mode.

At the back of the machine should be a socket for a pedal to plug in . Did your machine come with a pedal? If it did this is where to plug in if not you may consider obtaining one from TES. I’m certain Myron can provide one for that machine. We can also use automatic, but that depends on a lot of other stuff working as well including DC grounds. So lets start there. First measure for continuity across the red wire .This plugs in to the socket with the matching symbol but is also interchangeable with the black one. No Continuity is no Bueno! if there is a short in this wire your automatic wont work and you’ll get no DC current. It plugs into the red banana socket and the other end plugs into the chunky piece of round steel . This is the ground to the DC circuit. That rod when covered with a salt water towel conducts the posative anode for your dc circuit which is used for themolysis in automatic. If this doesnt work and you’ve no pedal , nothing will work.In the bubble test this would be in the glass of salt water .

Next up is a probe holder. . Look at the condition of the wires and the bnc connectors. Severe bends and kinks are not acceptable. You need good solid wires with no breaks. Use your continuity tester to check the connection between the center wire on the BNC connector and the other end of the wire at the brass fitting in the chuck of the probeholder. . No connection is no bueno, replace the wire/ probeholder… Plug it into the A( left) channel and switch the switch between the two BNC connectors to that channel.

having connected the pedal , anode, a-ysis time and intensity. I dont see settings for an automatic useage and dont know if it has one.

You need a contiguous DC circuit for galvanic. The body itself becomes the anode when you hold the anode rod and the needle is the cathode. Any breaks in the wire anywhere and your galvanic circuit wont work. This is of particular concern with older equipment. Kinks and damage tot he needlecord will cause high frequency not to function.

A good rule of thumb is to replace all cords when starting with an unknown machine, get new needlecords and new bana patch cords. They shouldnt be expensive and Myron or Jennifer from TES should be able to help you with this. Starting with new avoids many points of failure on unknown equipment. .

Hopefully this helps.